One-stop-shop

for clean air

We help to create a sustainable working and living environment by providing easy access to industrial dust extraction solutions. We supply all dust extraction, filtration and ventilation components as a one-stop-shop.

Contact usNew ATEX Certified products

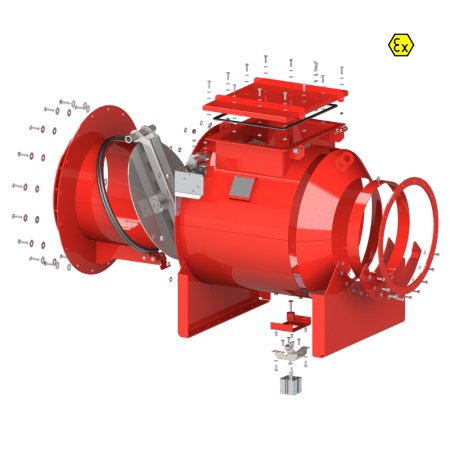

BADA-FAB St1

Explosion Isolation Valve

Formula Air has certified a new explosion isolation valve BADA-FAB according to the ATEX Directive 2014/34/EC, which is an excellent ATEX certified safety system specifically developed for the effective compartmentalization of explosions.

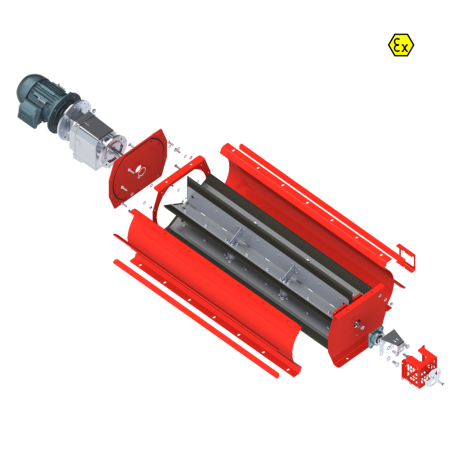

RVA-X 2024

Rotary Valve

Recently tested at FTZU, the new RVA-X rotary valve is certified according to ATEX Directive 2014/34/EC, available in lengths 250 - 1000 mm in 3 ATEX executions: ATEX 1D interior / 2D, 3D or safe zone exterior.

Services we offer

-

Direct

Our strong European presence allows us to ship our standard stock products within 48h.

-

Consulting

We can help you with our technical knowledge and expertise to choose the right solution.

-

Engineering

If you are looking for a non-standard product, it can be tailor-made by our engineers.

30 YEARS OF expertise IN manufacturing

Industrial dust

extraction products

Over the past 30 years, we have been manufacturing and distributing industrial dust extraction components in Europe. We support installers, contractors and OEM by providing the best air filtration and dust extraction solutions with the right expertise and innovative manufacturing techniques.

Our aim is to contribute to a clean & sustainable environment by providing you with the best dust extraction solutions ensuring:

- reliable partnership and seamless customer service

- easy access to standard products

- energy efficient solutions for industrial processes

- increased productivity & improved profitability

inspiration and social proof

Sustainable solutions for air filtration

Over the years we have developed various solutions to protect the environment and people from harmful particles, fibres, dust, gas, smoke and oil mist. We contribute to cleaner air by using modern technologies and less energy for our production, have less waste material and less CO2.

Our customers benefit from having easy access to complete and sustainable solutions. The high-quality air filtration systems we supply include duct systems, fans, filters, safety products, separators and rotary valves.

Start below to search our complete product portfolio

Happy Customers Share Their Experiences

Become our customer today

Join our happy customers and experience the benefits for yourself. Take the next step forward and contact your local team.