ONE-STOP-SHOP FOR

Separators &

rotary valves

For effective air filtration, we offer products for the dust pre-separation stage. It includes an extensive range of cyclones, separators and rotary valves.

- For all industries

- High reliability

- Efficient separation

- Many options

DUST PRE-SEPARATION WITH

Separators, cyclones & rotary valves

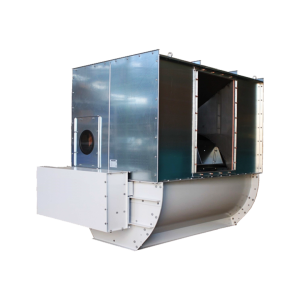

Our separator range is designed for various industries. Mainly covering agriculture, the paper, plastic, wood and cardboard industries. These high-performance separators ensure an effective separation of fine and heavy dust particles.

Cyclones are effective, low-maintenance, pre-separators for most industrial applications. But they can easily be replaced by rotational separators to ensure low-pressure loss and pressure-less separation in specific industries such as the paper and cardboard treatment.

Our standard rotary valves are designed to discharge dust and other materials with volumes ranging from 10 to 83 m³/h from filters and cyclones. They are equipped with a visual rotation indicator and include a rotation disc cover for safety purposes. The standard rotary valve range is complimented by ATEX-certified rotary valves for explosive environments, bigger dust volume models, and cast-iron models.

Standard installation including a cyclone and rotary valve.

Separators & Rotary Valves FAQ

For which material can the cyclones be used?

| Our cyclones are designed to handle a variety of materials, including but not limited to wood, plastic, metal, and organic dusts. However, the specific application and parameters such as air speed, type of dust, and particle size distribution may impact the performance of the cyclone. For more information on the suitability of our cyclones for your specific application, please contact our customer support team. |

What is the separation efficiency of the cyclones in %?

| Determining the separation efficiency of our cyclones is a complex process as it depends on various factors such as air speed, particle size and type of dust. Additionally, the efficiency can vary depending on the specific model, size and accessories of the cyclone dust extractor. Therefore, providing a specific percentage value for the separation efficiency of cyclone dust collector is difficult. Our team can assist you in selecting the appropriate cyclone separator for your application and determining its expected separation efficiency based on your specific needs. |

Up to which differential pressure can the rotary valves be used?

| It can be challenging to determine the maximum differential pressure that rotary valves can handle since it varies based on the specific type and size of the valve. To ensure that you select the most suitable valve for your application, please don't hesitate to contact our dedicated customer support team for further assistance. |

What are the air leakage rates of the rotary valves?

| The air leakage rates of our rotary valves depend on various factors, such as the pressure of the installation, type of rotary valve, size, and the types of dust separator blades used. |

Up to which temperatures can your rotary valves be used?

| Our standard RVA & RVB rotary valves for dust extraction are equipped with neoprene rubber blades that have a maximum temperature range of +80ºC. |