Producing new heat recovery system for

Recycling industry

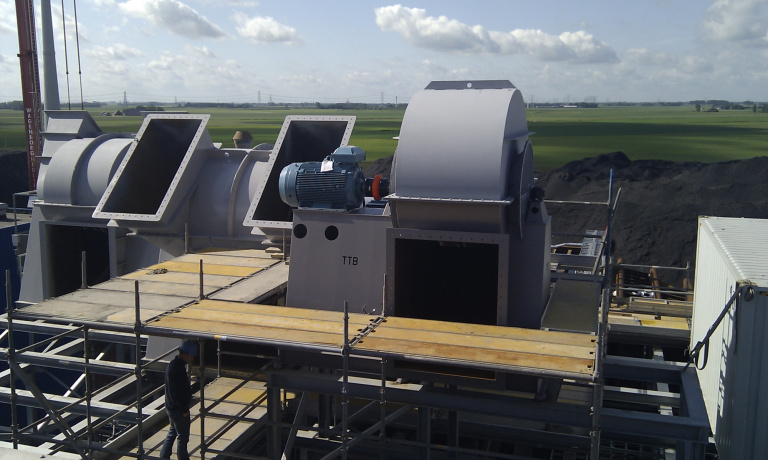

Location: Eemshaven, the Netherlands

Industry sector: recycling

This project was carried out by our customer working partner with Formula Air.

Background

Contaminated soil and sludge is shipped and stored separately in order to prevent any further contamination. It is then transported on conveyor belts into large drums which are heated at temperatures up to 1200°C to remove unwanted chemicals. The hot air produced as a by-product of this process is filtered and passed through a heat exchanger so it can be converted to energy which is used for other purposes.

Challenge

To assume complete control of developing a new heat recovery system, from measuring to planning and production, and then to deliver all components within 10 weeks. Having to meet such a tight deadline within a limited budget – meant we had to speed up the production process where it mattered the most.

Solution

A 3D visualization of the project was made in the CAD-CAM software Solidworks. We started the production after receiving approval from the customer. We produced and supplied all the necessary piping (some of which were pipe sections with dimensions of 3800 mm x 3800 mm). Some pipework was produced in separate modules that could easily be assembled and installed on site. Various materials have been used, including HB400, SS304 stainless steel, galvanized steel and 4 mm thick “COR-TEN” steel. This proves again that we can deliver effective solutions beyond the standard thickness range (1-3 mm).

Our customer received everything it needed two months earlier than they had initially envisaged, so was naturally extremely pleased. A further benefit was that the new installation was 30% more efficient than the previous one. Equally as important was the fact that we took responsibility out of the hands of our customers, bringing peace of mind and the convenience that we could function as a one-stop shop and meet all its demands.