ONE-STOP-SHOP FOR

ATEX & safety

In today's industrial landscape, ensuring the safety of personnel and the production facility is paramount, especially when operating in potentially explosive atmospheres. At Formula Air, we are dedicated to providing comprehensive solutions that align with the 2014/34/EU ATEX Directive, delivering top-notch protection against the effects of explosions.

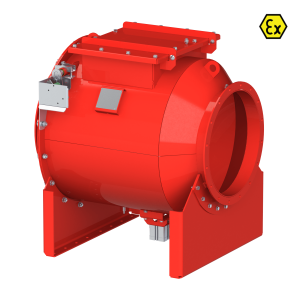

- ATEX rotary valves

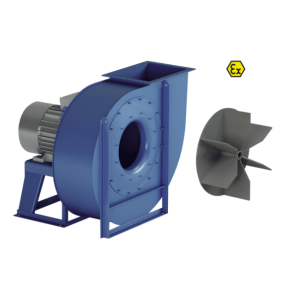

- ATEX explosion isolation valves

- Fire dampers and extinguishing systems

- Explosion relief and suppression components

- Level, dust, rotation sensors

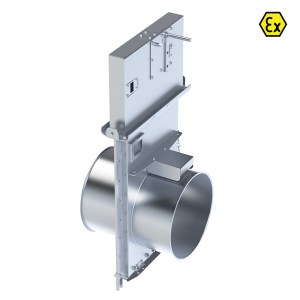

FEATURED PRODUCT:

BADA-FAB

Explosion Isolation Valve

ATEX-certified solution designed to prevent explosion propagation through quick and effective isolation. Watch the video to see how the BADA-FAB valve functions and learn about its benefits in enhancing process safety.

ATEX CERTIFIED PRODUCTS FOR

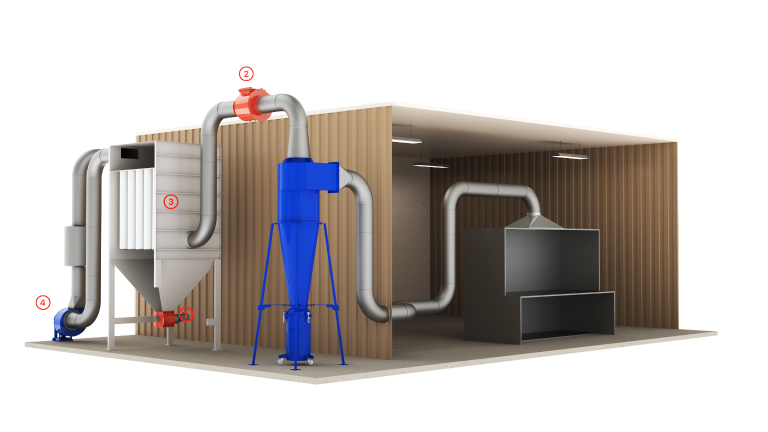

Complete ATEX installation

When it comes to managing hazardous environments, we offer a comprehensive range of ATEX-certificated products to create a fully integrated ATEX installation. Our ATEX-certified BADA explosion isolation valves and rotary valves act as pivotal elements in preventing the spread of dust explosions. By choosing our products, you are investing in an additional layer of safety and ensuring compliance with ATEX standards.

Local Safety and Environmental Legislation

It's important to note that in ATEX installations, the ducting and associated components must adhere to local safety and environmental legislation. At Formula Air, our experts are committed to providing you with the highest level of assistance within the bounds of our knowledge and expertise of the ATEX regulations.

Example of an ATEX compliant installation

1 - RVA-X Rotary Valve; 2 - ATEX Explosion Isolation Valve; 3 - ATEX Filter; 4 - ATEX Fan;

At Formula Air, we are committed to providing cutting-edge ATEX-certified solutions that prioritize safety, compliance, and performance. Contact us today to discuss your specific needs and discover how we can help you enhance safety and productivity in hazardous environments.

ATEX & safety FAQ

Why is an ATEX Explosion Isolation Valve necessary when operating in a hazardous atmosphere?

An ATEX Explosion Isolation Valve is necessary in hazardous atmospheres to enhance safety, contain explosions, ensure compliance with regulations, mitigate risks and maintain operational continuity. It is a crucial component of a comprehensive explosion protection strategy in hazardous environments.

What happens if you do not have an ATEX Explosion Isolation Valve installed?

The installation of an ATEX Explosion Isolation Valve is crucial for the safeguard of your dust extraction system in the event of an explosion. Without one, the explosion can spread through your installation and result in costly downtime while the affected system components are replaced.

How does the ATEX Explosion Isolation Valve protect your system during an explosion?

The ATEX Explosion Isolation Valve is designed to remain open during normal operation as air flows through it. In the event of an explosion, the explosion causes a backdraft in the ducting which triggers the valve to close by its own weight, blocking the ducting. In general the working principle of an explosion isolation valve would make the pressure wave and flame push in the opposite direction of the airflow, forcing the flap against the frame of the device and blocking the rest of the ducting.

Where should the ATEX Explosion Isolation Valve be installed?

When installing an ATEX Explosion Isolation Valve, it's important to follow the guidelines outlined in the user manual. The manual contains detailed instructions tailored to the specific model and intended use of the valve.