YOUR ONE-STOP-SHOP FOR INDUSTRIAL FILTERS:

CHOOSING THE RIGHT FILTER TYPE FOR YOUR INDUSTRY

Selecting the appropriate filter type for your industry is essential to ensure optimal dust filtration, regulatory compliance and the overall well-being of workers. Many industrial processes generate dust and gas emissions that require specialized treatment, making careful consideration of filtration systems a priority.

Formula Air offers a wide range of high-quality dust extraction filters to meet the demands of various industries. Whether your application involves common industrial processes or ATEX environments, our products deliver efficient and reliable performance. Our technical pool is here to assist you in finding the right solution for your needs. If you'd like to speed up the process, simply fill out the form, which you can access by clicking the button below.

Common industrial process applications:

-

Coating and painting:

For both dry coating (e.g., powder coating) and wet coating processes (e.g., paint or lacquer), our filtration systems protect employees from airborne particles and facilitate clean air recirculation.

-

Plasma and laser cutting:

Our cartridge filters efficiently capture fine particles generated during cutting processes, ensuring a safer and cleaner work environment.

-

Welding:

Fume filtration is made efficient with cyclonic cartridge filters and dust buckets, capturing harmful particles produced during welding.

-

Mechanical and metalworking:

Oil mist filters effectively separate harmful oil mists and emulsions, maintaining a clean and safe workplace.

-

Recycling and waste disposal:

A combination of cyclones, filters, and electrostatic filters minimizes dust, solvents and gas emissions, reducing the environmental impact of waste disposal and recycling operations.

-

Agro- and food:

Bag and cartridge filters, including active carbon filters, address the air filtration needs of agri-food processes, ensuring clean air throughout production.

-

Petrochemical and pharmaceutical:

Our filtration systems support various stages of packaging and waste treatment in these industries.

-

Woodworking:

Baghouse and cartridge filters effectively capture airborne particles and wood chips, reducing fire risks and health hazards.

-

Centralized cleaning:

High vacuum systems with reinforced cyclonic cartridge filters and bag filters offer efficient separation across multiple sectors.

One-stop-shop for all dust extraction needs

With over 30 years of experience, Formula Air is your trusted partner for all dust extraction requirements. Our solutions are tailored to meet the highest industry standards and include the following options:

Cartridge filters

- Use

Ideal for welding smoke, grinding dust, cutting smoke and dusty air containing metals, plastics or mixed powders.

- Features

Compact design, easy to install, move and transport.

- Airflow

Up to 100 000 m3/h.

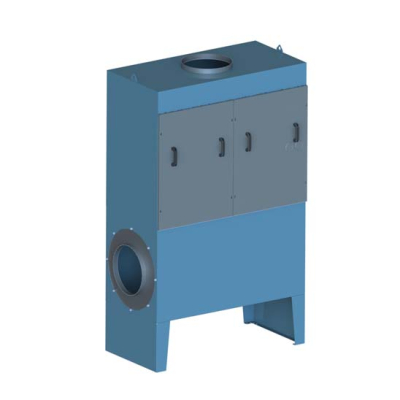

Baghouse filters

- Use

Designed for material filtration in wood, paper, cardboard and plastic industries.

- Features

High performance filters with pneumatic cleaning.

- Airflow

Up to 10 000 m3/h.

Oil mist filters

- Use

Effective in separating oil mist aerosols from processing machines.

- Features

Ideal for environments where cooling lubricants are used.

- Airflow

Up to 16 000 m3/h.

High vacuum filters

- Use

Suitable for centralized cleaning or small hand tool applications.

- Features

Equipped with compressed-air cleaning, timer control, side channel blower and sound enclosure for easy transport and efficient operation.

- Airflow

Up to 1 500 m3/h.

Air purifier filters

- Use

For ultra-fine particle filtration, including fine dust, viruses, bacteria, fungi and gas.

- Features

Low in maintenance and noise levels.

- Airflow

Up to 48 000 m3/h.

Your ideal filtration solution awaits

Our diverse product range offers comprehensive solutions for various filtration requirements. These filters can be paired with pre-filters like cyclones or fine dust filters such as H9, HEPA, active carbon or electrostatic filters to meet your specific needs.

Contact our team today to explore how our filtration solutions can optimize your operations, enhance efficiency and contribute to a cleaner, healthier environment. Together, we’ll ensure your filtration system aligns perfectly with your industry’s demands.